Preservation Periodical: Volume 3, Issue 2

Summer 2024

National Museum of Natural History

Cornice Repair Project Completion

By Millie Latack

This spring, AHHP with Aeon Preservation Services completed an emergency cornice repair project at the National Museum of Natural History (NMNH). The emergency repair came about as part of a design project to restore part of the exterior facade of the building. Analysis of facade conditions alerted the SI of sizable spalls at the granite cornice of the building in multiple locations. Some spalls required immediate action to stabilize the area preventing any falling debris above active areas below.

Construction of this iconic Neoclassical style building was completed in 1911 primarily of Mount Airy and Bethel Granites. Mount Airy is light grey granite that has a unique composition with the inclusion of accessory minerals, namely feldspar. Granites with these inclusions are more susceptible to microcracking exacerbated by freeze-thaw and thermal shock, uncommon with typical granites. Over a century of use and weathering have created some imperfections in the exterior stone. As a first step to address this, a site survey was conducted by Aeon Preservation Services to assess conditions around the perimeter of the building in December 2022. Results of that survey showed a concentrated amount of failure conditions at the third-story cornice above the west loading dock.

In total, 52 spalls were estimated over the west loading dock, but after removing the copper roof flashing an additional 23 spalls were found. Stone cracking and spalls were primarily at locations where flashing was secured with metal anchors. These spalls ranged in sizes from 2 inches wide up to 16 inches. Also found after the removal of the coping were deteriorated iron cramps used to secure the parapet stones. In total, 23 eight-inch-long cramps required replacement with stainless steel cramps mortared into the granite to prevent the same extent of deterioration from happening again.

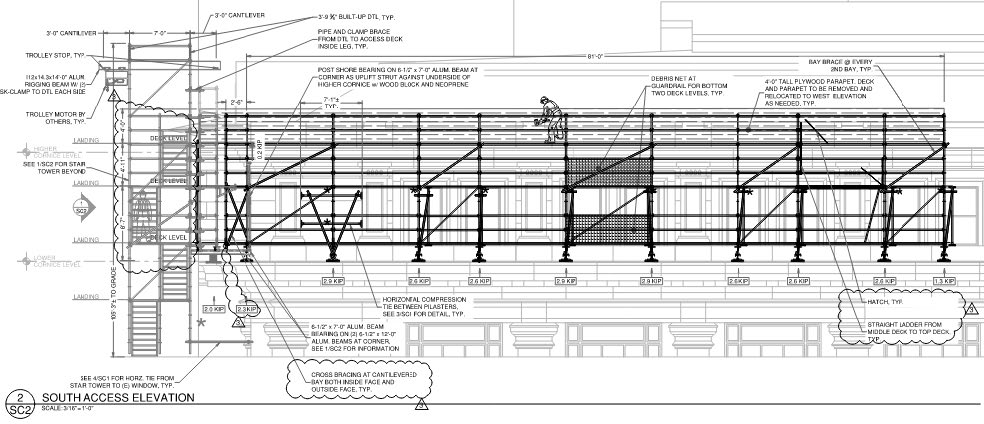

In order to safely access the repair area, a cantilevered scaffold was designed to set on the upper levels of the building minimizing needed scaffold and potential incidental building damage. This design afforded an expedited installation period with minimal impact on the daily operations of the Museum at the loading dock area. The scaffold spanned below and above the cornice to allow for additional cleaning, repointing, and recaulking around the windows.

After spalls were removed, the stone was cleaned in preparation for dutchman repairs. Sections of granite that had smaller spalls were removed and cut to be reused in the repairs where possible. This and supplemental replacement stone was then shaped, mortared, and repointed along the span of the cornice. The steel cramps were mortared into the stone as well, replacing those that were hidden under the parapet flashing. New weatherproofing underlayment and copper flashing finished off the project. Within roughly two months, the west loading dock was stabilized and improved upon to ensure a secure continuation of the Natural History Museum exterior envelope.